When it comes to applying ceramic coatings to your vehicle, one of the most important factors to consider is the cure time. The cure time refers to the amount of time it takes for the coating to fully bond and harden onto the surface of the vehicle. This process is crucial in ensuring that the coating provides maximum protection and durability.

Typically, ceramic coatings will have a recommended cure time provided by the manufacturer. This can range from 24 hours to several days, depending on the specific product. It’s important to follow these guidelines to ensure that the coating cures properly and provides the desired results.

Factors Affecting Cure Time

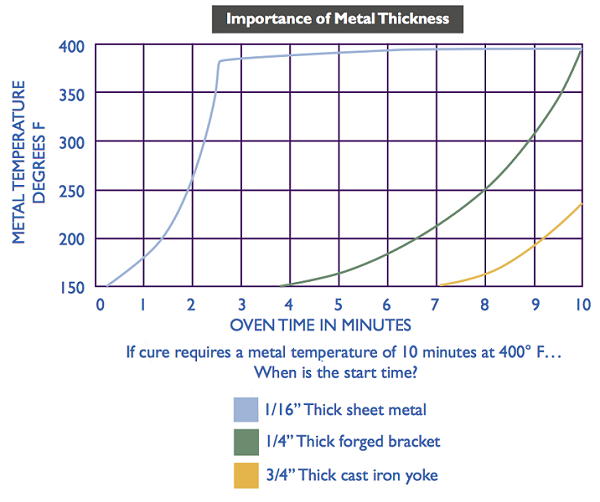

Several factors can affect the cure time of a ceramic coating. These include the temperature and humidity levels during application, as well as the thickness of the coating. In general, higher temperatures and lower humidity levels will speed up the curing process, while thicker coatings may require longer cure times.

It’s important to refer to the manufacturer’s instructions and recommendations when it comes to curing your ceramic coating. Failure to follow these guidelines could result in a coating that doesn’t fully cure, leading to reduced performance and durability.

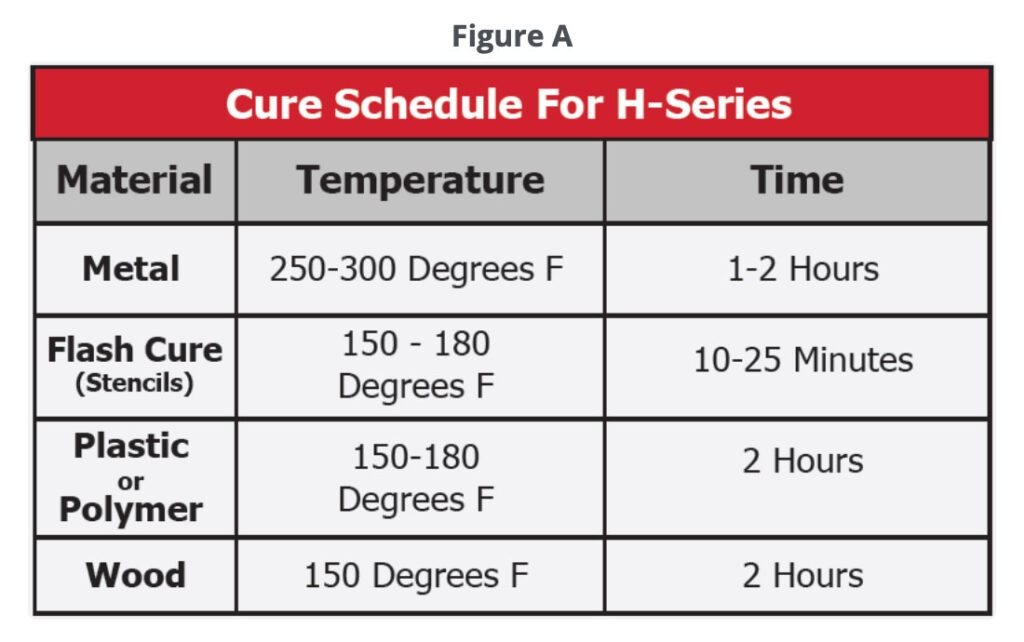

Ceramic Coating Cure Time Chart

Here is a general guideline for ceramic coating cure times based on common temperature and humidity levels:

| Temperature | Humidity | Cure Time |

|---|---|---|

| 70°F – 90°F | 30% – 50% | 24 – 48 hours |

| 90°F – 110°F | 10% – 30% | 12 – 24 hours |

| Above 110°F | Below 10% | 6 – 12 hours |

Keep in mind that these are just general guidelines and may vary depending on the specific product you are using. Always refer to the manufacturer’s recommendations for the most accurate cure time for your ceramic coating.