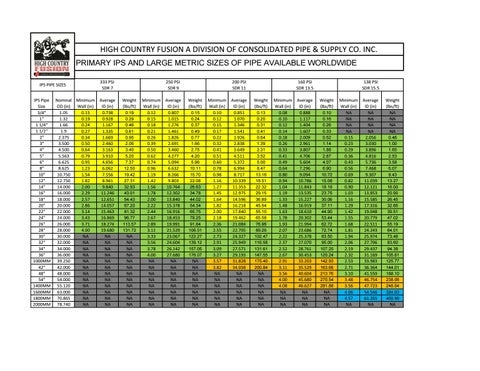

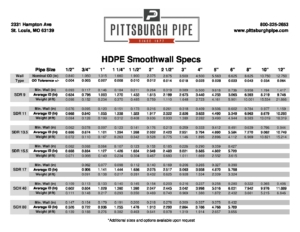

HDPE pipe fusion is a critical process in joining high-density polyethylene (HDPE) pipes to create a leak-proof and durable pipeline system. The fusion time is the duration required for the fusion process to complete, ensuring a strong bond between the pipes. The fusion time chart provides guidelines on the fusion time based on various factors such as pipe size, wall thickness, ambient temperature, and fusion machine type.

It is essential to follow the fusion time chart meticulously to achieve a proper fusion and prevent any potential leaks or failures in the pipeline system. The fusion time may vary depending on the specific fusion machine used, so it is crucial to refer to the manufacturer’s guidelines and recommendations for precise fusion times.

Factors Affecting Fusion Time

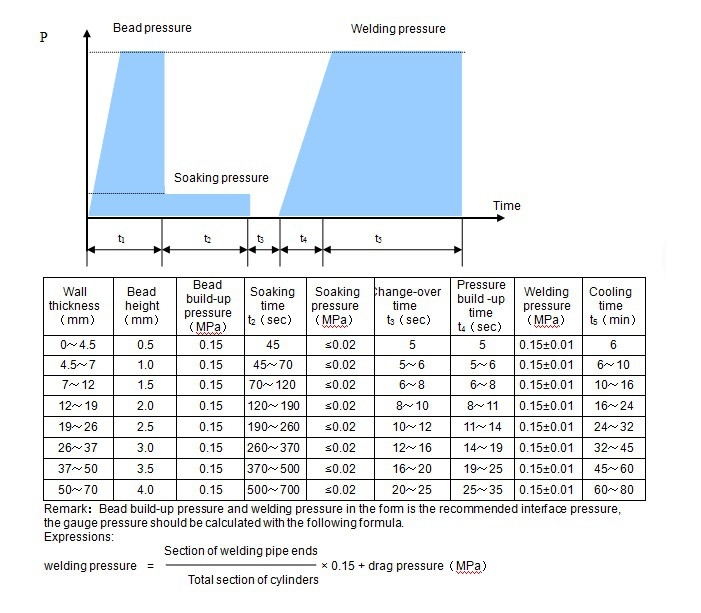

Several factors can influence the fusion time required for HDPE pipe fusion, including pipe size, wall thickness, ambient temperature, fusion machine type, and operator experience. Larger pipe sizes and thicker walls may require longer fusion times to ensure a proper bond between the pipes. Additionally, ambient temperature can impact the fusion process, with colder temperatures typically requiring longer fusion times compared to warmer conditions.

The type of fusion machine used also plays a crucial role in determining the fusion time. Different fusion machines have varying heating capabilities and fusion settings, which can affect the fusion process’s speed and efficiency. Operator experience and skill level are also critical factors, as improper fusion techniques or insufficient heating can lead to weak joints and potential failures in the pipeline system.

Importance of Following Fusion Time Chart

Adhering to the fusion time chart is crucial to ensure a successful and reliable fusion process for HDPE pipes. Proper fusion times are essential for creating strong and durable joints that can withstand the rigors of underground installation and fluid transportation. Deviating from the recommended fusion times can result in incomplete fusion, weak joints, and potential leaks or failures in the pipeline system.

By following the fusion time chart meticulously and considering all relevant factors, operators can achieve consistent and high-quality fusion results for HDPE pipes. It is essential to prioritize safety, quality, and precision in the fusion process to guarantee the long-term performance and reliability of the pipeline system.

By understanding the fusion time chart and its importance, operators can ensure a successful fusion process and a robust pipeline system that meets the demands of various applications and industries.