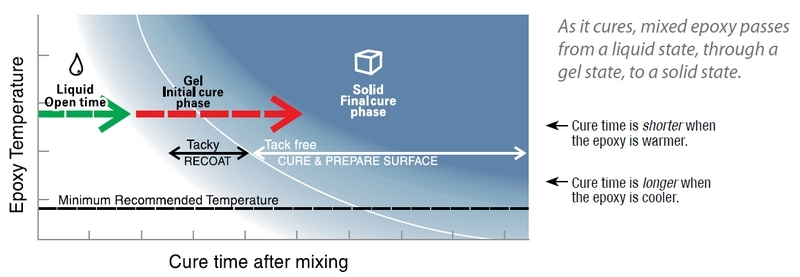

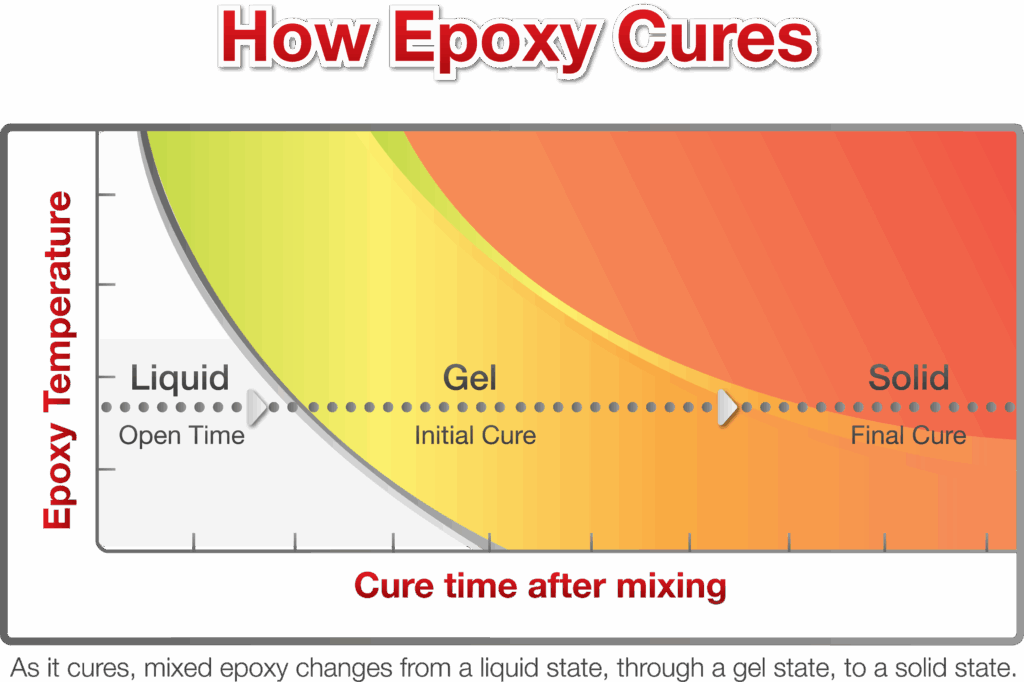

Epoxy is a popular choice for coatings, adhesives, and sealants due to its durability and versatility. One of the most important factors to consider when working with epoxy is the cure time. The cure time refers to the time it takes for the epoxy to fully harden and reach its maximum strength.

It’s crucial to follow the manufacturer’s instructions regarding the cure time to ensure the best results. Factors such as temperature, humidity, and the type of epoxy used can all affect the cure time. Consult an epoxy cure time chart to determine the optimal curing conditions for your project.

Factors Affecting Epoxy Cure Time

Several factors can impact the cure time of epoxy. Temperature plays a significant role, with higher temperatures typically speeding up the curing process. Humidity levels can also affect cure time, as excess moisture in the air can interfere with the curing process.

Additionally, the type of epoxy used and the thickness of the application can influence the cure time. Thicker layers of epoxy will take longer to cure than thinner layers. Be sure to allow for proper ventilation and curing time to achieve the best results.

Tips for Ensuring Proper Cure Time

To ensure that your epoxy cures properly and reaches its full strength, follow these tips:

1. Refer to the manufacturer’s instructions for recommended cure times and conditions.

2. Use a thermometer and hygrometer to monitor temperature and humidity levels during curing.

3. Avoid applying epoxy in extreme temperatures or high humidity conditions.

4. Allow for proper ventilation to aid in the curing process.

5. Test the epoxy for hardness before subjecting it to heavy use or stress.