When using a heat press for printing on garments or other items, it is crucial to have the right combination of time and temperature to achieve the best results. The time and temperature settings will vary depending on the type of material you are working with, as well as the type of transfer paper or vinyl you are using.

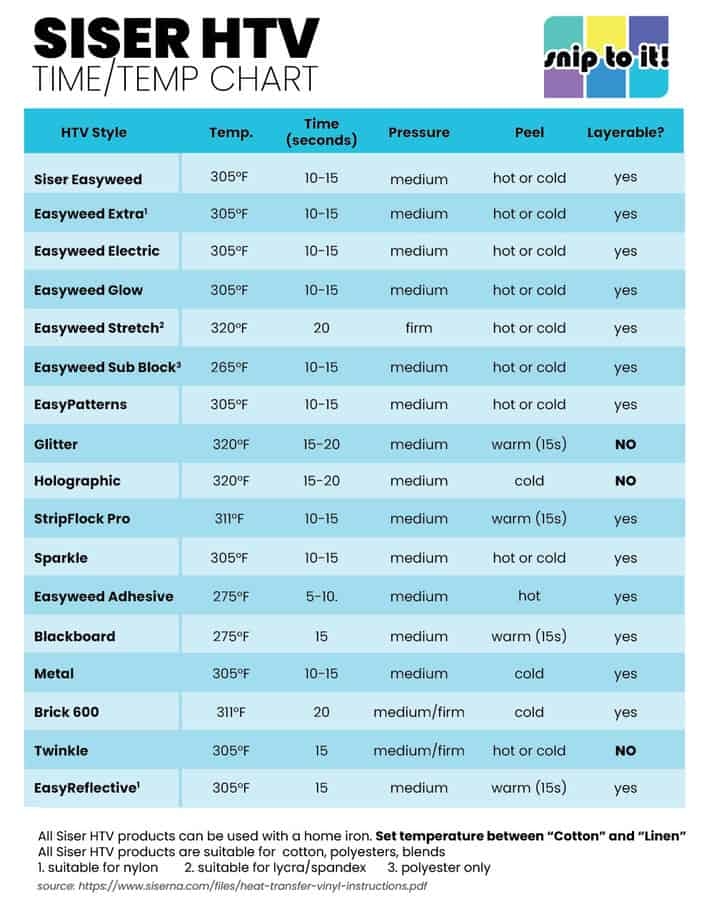

It is important to follow a heat press time and temperature chart to ensure that your designs are properly applied and adhere to the material. This will help prevent any fading, peeling, or cracking of the design over time.

Choosing the Right Time and Temperature

Before starting your heat press project, it is essential to consult a heat press time and temperature chart. This chart will provide you with guidelines on the recommended settings for different materials and transfer types.

For example, when working with cotton or polyester fabrics, the recommended temperature may be around 350-375 degrees Fahrenheit for 15-20 seconds. However, when working with nylon or spandex, you may need to lower the temperature to prevent scorching or melting of the material.

Tips for Successful Heat Press Printing

Here are some tips to keep in mind when using a heat press:

1. Always pre-press your garment to remove any moisture or wrinkles before applying the design.

2. Use a heat-resistant tape to secure the transfer paper or vinyl in place to prevent shifting during pressing.

3. Experiment with different pressure settings to find the right amount of pressure for your specific material and design.

4. Allow the garment to cool completely before peeling off the transfer paper or vinyl to ensure a long-lasting result.